What Happens When Your Wood Packaging Isn’t ISPM-15 Compliant?

ISPM-15 exists to reduce pest damage in export shipments. Learn more about the standard’s requirements and the consequences of noncompliance.

ISPM-15 exists to reduce pest damage in export shipments. Learn more about the standard’s requirements and the consequences of noncompliance.

In the packaging and transportation industries, there are a wide array of regulations that contractors and manufacturers must follow.

While they can seem complicated, it is essential that they’re followed. Among some of these regulations is ISPM-15, a standard that exists specifically for certain types of wooden packaging.

ISPM-15 refers to the International Standards for Phytosanitary Measures No. 15. It’s a regulatory document developed by the International Plant Protection Convention (IPPC).

The standard exists to ensure pest-free, disease-free international shipments of solid wood materials. Shipping contaminated boxes has been shown to detrimentally impact ecosystems in countries receiving defiled wood.

Standards implemented by the ISPM-15 cover storage areas, aircraft, containers, vessels, soil, and anything else that could contain and spread insects and diseases.

As the name states, ISPM is an international requirement. However, not all countries require ISPM-15 compliance. According to the U.S. Department of Agriculture, when shipping goods from the United States, the following countries require ISPM-15 compliance:

This standard outlines various requirements to reduce pest risks for wood packaging materials (WPMs) that exceed six millimeters in thickness and are used for export purposes, with the exception of processed wood material, including plywood, oriented strand board, fiberboard, press board, and cardboard.

The first requirement outlined in ISPM-15 is that all regulated WPM must be made from debarked wood. Compliant wood will contain no more than 3 cm of bark in width or, if exceeding 3 cm in width, shall be no more than 50 sq cm.

The second requirement is treating the wood. ISPM-15 recognizes three treatments:

Only an NPPO (national plant protection organization) or an organization authorized by the NPPO are allowed to approve the use of an ISPM-15 mark. Per guidelines, the approval system used by the NPPO or authorized organization should:

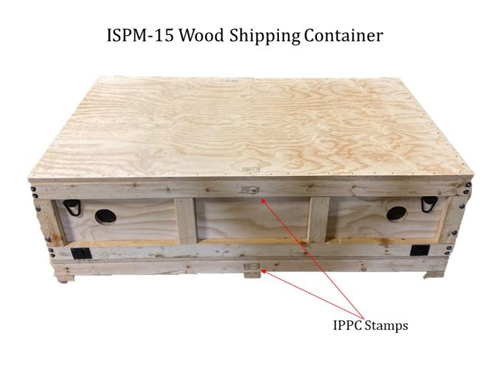

Per ISPM-15 requirements, the marking on the WPMs must contain:

There is no size requirement for the mark, unless otherwise noted by the NPPO, but the mark must be highly visible on the packaging. ISPM-15 requirements prefer that the mark appear twice on opposite exterior sides of the packaging.

ISPM-15 standards must be applied to all WPMs, including collars, dunnage, reels, pallets, crates, and bracing, unless it was created with adhesives, pressure, heat, or any combination of these three manufacturing methods. Exempt WPMs include:

Although non-compliance with ISPM-15 regulations is handled differently in countries, the penalties for noncompliance involve similar damages. These retributions include:

If non-compliant packaging manages to leave the U.S. and reaches its destination, the WPMs will be subjected to that country’s regulations regarding ISPM-15. Some countries may ship the package back to the U.S. or simply fumigate the whole shipment.

However, businesses that knowingly export non-compliant WPMs are putting their shipments at risk. When you send noncompliant packages, you’re increasing the risk of costly damage due to contamination and shipment delays that may ultimately keep you from hitting your deadline.

If you’re concerned about compliance, the best decision you can make is to partner with an NPPO-approved facility, like Export Corporation. Founded over 80 years ago, we provide custom packaging solutions to manufacturers in the military, aerospace, automotive, and commercial sectors. We have many years of expertise in packaging requirements, including ISPM-15, and can help you understand how to stay ISPM-15 compliant.

To request a consultation or to learn more about our services, please fill out our online form today.

Send us details about a packaging project you need, and a member of our expert team will be in touch.