The Top 3 Ways You Can Reduce Automotive Packaging Costs

Transporting automotive parts, like engines, windshields, and body components can be challenging. Supply chain issues over the pandemic have caused unpredictability in packaging supply availability. Then, the rise in fuel costs caused shipping fees to increase. In 2022, the transportation industry also saw a surge in workplace shortages and other issues, which resulted in more shipping delays and package mishaps. And on top of all these challenges, the U.S. inflation rate rose to an all-time high.

For manufacturers, these issues are cause for concern. Because there are fewer skilled drivers on the road, this opens up the possibility of transportation issues and potential product damage, which can cost automotive manufacturers thousands of dollars. And, because the inflation rate is now at 7.1%, automotive manufacturers must also face the rising costs of both packaging and shipping fees.

Although most of these challenges won’t go away overnight, there are still three primary ways manufacturers can reduce packaging and shipping costs in the coming year, starting with how the packaging is designed.

1. Optimize the Packaging Design

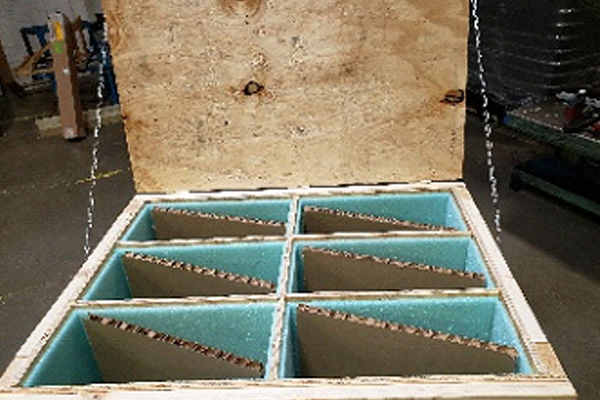

Automotive packaging can be custom-designed without violating federal compliance regulations or compromising protection.

First, consider which materials you’ll need, which depend on the components you’re shipping and any regulations surrounding those components. For example, bumpers require heavy-duty plastic bags or padding to prevent dents and scratches during transportation, while wheels need to be covered with a plastic liner.

The prices of certain packaging materials, including wood, have continued to rise since 2022, while others, including rigid plastics, are predicted to decrease by 2023. As you create your design, are there areas where you could save money simply by switching to a more cost-effective (but compliant) material?

Additionally, having the right design for your component(s) enhances protection during transportation. When you have the correct protective materials, you won’t have to worry about unexpected part replacement costs. The first step in creating a cost-efficient design is working with a professional automotive parts packaging company. A third-party packaging company will have engineers who can identify areas where you can save money and help you develop custom packaging best suited for the components you’re shipping.

2. Reduce Dimensional Package Weight

Next, you need to know how many components you are shipping in one package. How much will that packaging weigh? Can you reduce the weight of the package?

Instead of calculating the physical weight of a package to determine shipping costs, verify the dimensional weight (DIM) and the associated cost of shipping based on that weight. DIM is calculated by multiplying a package’s height, width, and length to get the cubic size. (Note: be sure to measure any bulges or irregularities to prevent discrepancies in your calculation). Then, you divide that cubic size by the DIM divisor, which varies between freight carriers. The DIM number is then compared to the physical weight of the package, and the shipment cost is decided by whichever number is the highest.

In other words, smaller packages will usually cost much less to ship than larger packages containing unused space.

3. Evaluate Shipping & Kitting Options

Lastly, consider consolidating compatible components in one package or shipping parts in bulk. While some more delicate or environmentally sensitive components require individual shipping containers, many smaller parts can be packed safely together and shipped with more cost efficiency. Also, remember that certain carriers will have dangerous/hazardous goods regulations that limit how many dangerous goods can be shipped in one package.

Reduce Automotive Packaging Costs With Help From Export Corporation

As a manufacturer, you’re focused on producing high-quality parts for your customers. When it comes to transporting these parts, you can save time, money, and stress by working with a professional packaging company like Export Corporation.

As an all-in-one automotive packaging provider, we offer design, labeling, light assembly, kitting, warehousing, and preservation services. We’re also ISO 9001- and ISPM-15-certified to help you ensure compliance with federal and freight carrier rules and regulations.

If you want to learn more about our services and capabilities or have general questions about automotive packaging, please fill out our online form today to speak with a representative.