How to Meet Mil Spec Packaging Requirements

Mil spec packaging often requires memorizing dozens of codes. If you’re not sure how to stay compliant during this process, read this article.

Mil spec packaging often requires memorizing dozens of codes. If you’re not sure how to stay compliant during this process, read this article.

Military packaging specifications involve packaging and shipping protocols established by the U.S. Defense Logistics Agency (DLA). Unless DLA packaging standards are met, companies risk delays, repackaging materials at their expense, and the possible cancellation of a military contract.

At Export Corporation, we understand how challenging mil spec packaging can be—that’s why we’ve put together this article. Keep reading to learn more about mil spec packaging protocols and what needs to be accomplished to stay compliant with DLS packaging rules.

Most codes mandate specific labeling requirements on hazardous, temperature-sensitive, and fragile shipments.

If packaged materials require special instructions, those instructions most likely need to be on an exterior label. Barcodes must be placed on precise areas of packaged materials as well.

Failing to adhere to mil spec label policies could result in delays, lengthy inspections, and possible fines for noncompliance.

Applications and features of packaging labels include:

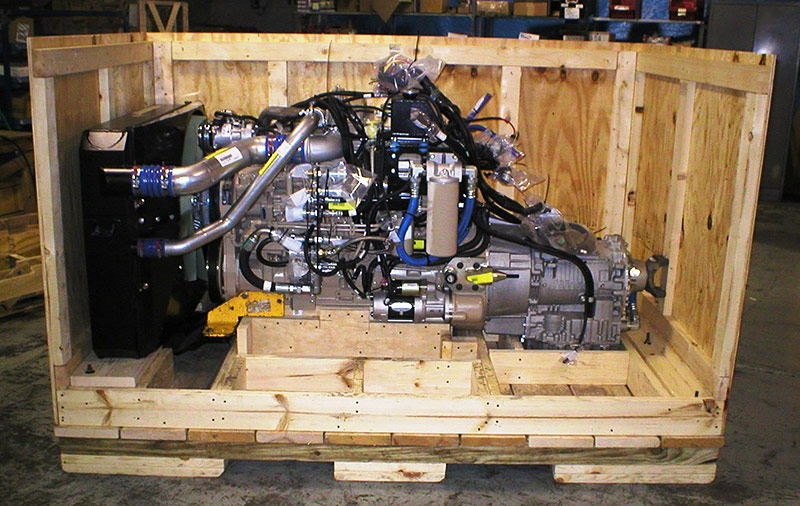

Palletization or palletizing refers to the placement of items, boxes, etc. on a pallet for the purpose of storing or shipping these items.

Optimizing palletization not only involves knowing how to stack products in a way that maximizes the product load by volume and weight, but also that the pallet remains secure enough to prevent damage to the products.

Although not all shipments delivered to the U.S. Department of Defense (DoD) can or must be palletized, most require special palletization criteria associated with material codes.

Packaging codes instruct contractors on what items can be palletized together, how much weight can be placed on pallets, and the dimension allowances of pallets.

Codes further restrict what items can be palletized together safely and whether wood pallets must be treated with special agents before being shipped.

The DLA cites the following palletization codes used for military shipments:

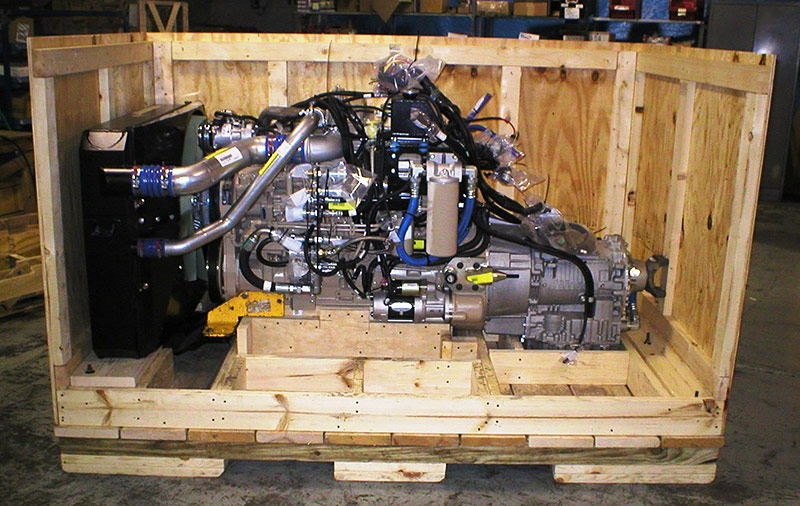

Tertiary packaging refers to the exterior packaging materials that are used to protect products from damage.

Packaging codes clearly define what type of tertiary packaging materials must be used to prevent damage to specific products during shipment.

For example, items susceptible to corrosion typically require heat-sealed bags, while products that are sensitive to grease or fluids should be protected with various foil-type wraps.

Packaging codes also indicate that all electronic products should be encased in electrostatic bags that inhibit the nullification of semiconductor devices.

Common packaging codes include:

MIL-PRF-131K: Vapor/water barrier materials that are divided into different classes. Class I is vapor/water material made from poly laminated foil. Class II materials are made from poly-coated Kraft foil laminate. Class III barrier materials are composed of woven scrim laminated foil.

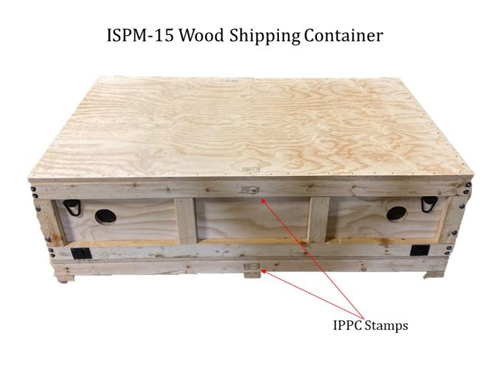

Regardless of the product your company is shipping, military inspectors will confirm compliance with codes, as well as test the durability and quality of packaging materials. It is vital that the packaging materials you use can reliably withstand water, oil, grease, punctures, and other externally-caused damage. Also, be aware that most wooden pallets or crates must be heat-treated per ISPM-15 requirements to prevent possible pest damage.

The DLA is constantly posting updates to military packaging standards. The last update posted by the DLA on their website occurred in 2021.

Some updates may be minor and fly under the radar of busy contractors. Export Corporation keeps track of DLA updates in real-time to ensure your packaged goods meet the newest mil spec packaging requirements.

Working with a leading military packaging company like Export Corporation is the best way to guarantee your packages are not delayed, rejected, or fined for noncompliance. We offer assistance with storing, labeling, military packaging, packing, and preservation.

Mil spec packaging involves thousands of codes that the U.S. government rigorously upholds. One small deviation from a packaging code could cost your company more than just a delay.

If you have questions about mil spec packaging requirements, or would like our team to help you design custom, compliant packaging—contact us today for a free consultation.

Send us details about a packaging project you need, and a member of our expert team will be in touch.