Inflation has caused an increase in automotive packaging and shipping costs. This article explains how you can reduce these costs.

Continue reading...

Mil spec packaging often requires memorizing dozens of codes. If you’re not sure how to stay compliant during this process, read this article.

Continue reading...

One of the best ways businesses can reduce the costs of shipping is by creating effective packaging designs. This article covers three categories and ways to help.

Continue reading...

Are you shipping goods internationally? Read this article by Export Corporation to learn more about the seven most important factors of export packaging.

Continue reading...

Packaging requirements exist for very good reasons. In this post, our experts at Export Corporation discuss what happens when you aren’t ISPM-15 compliant.

Continue reading...

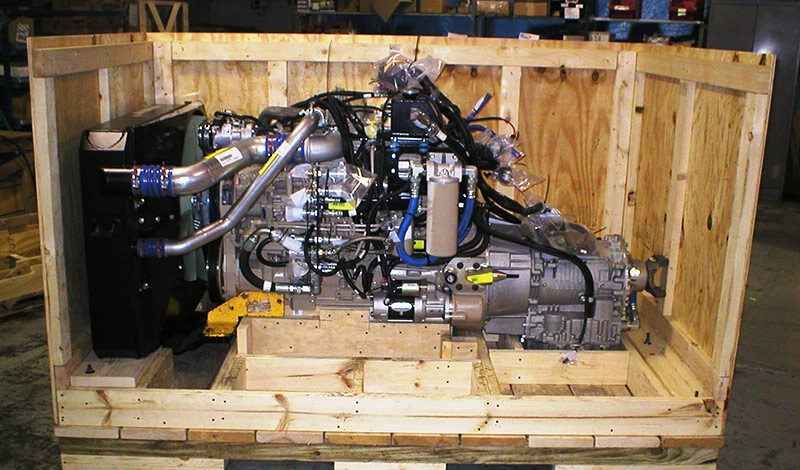

Don’t overcomplicate packaging. Save money, reduce waste, and meet deadlines by avoiding these six common aerospace crating mistakes.

Continue reading...

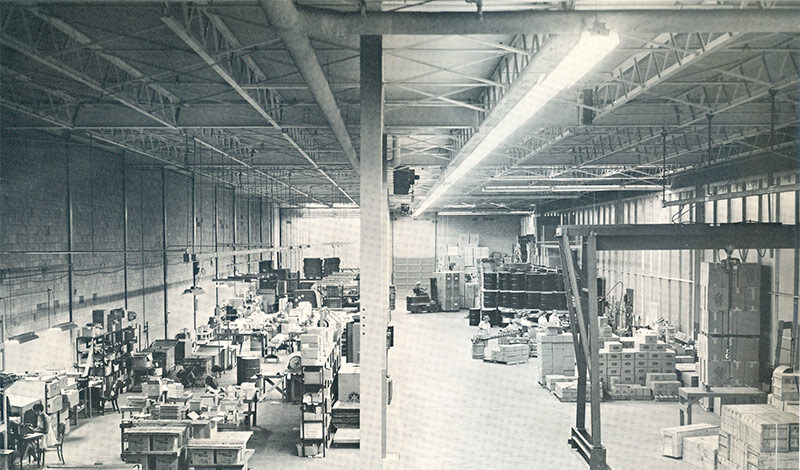

Do you need industrial packaging services? Find out more in this article from Export Corporation, a trusted industrial packaging provider.

Continue reading...